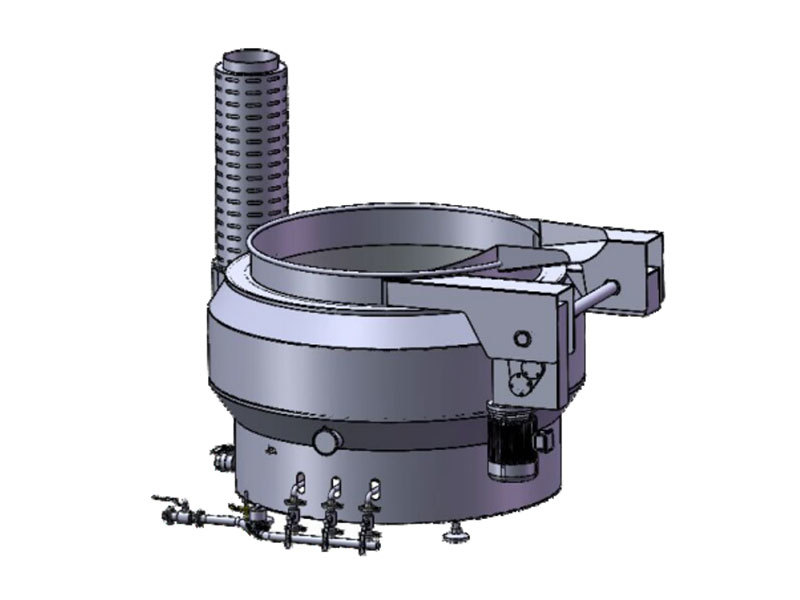

Douban paste production line

Professional manufacturer of condiment machinery

Product Description

This production line can realize continuous production, which can effectively save labor and improve production efficiency.

1. Fresh peppers are transported to a winnowing machine through a lifting conveyor. After the winnowing machine removes some weeds, broken leaves and dust from the peppers, they are transported to the pepper washing machine.

2. Under the action of high-pressure water and strong bubbles, the pepper is fully dispersed, rolled, and cleaned, and the sand falling off the surface of the pepper sinks into the bottom isolation chamber, and no overturning or backflow will cause re-pollution.

3. The washed material is sprayed and cleaned and sent to the dehydration conveyor. The dehydration conveyor is conveyed by a 304 stainless steel mesh belt. The upper part is equipped with a powerful fan, and the lower part is equipped with a vibrating roller, which can remove most of the water. The bottom of the equipment is equipped with a tray and a circulating water tank to pump the fallen water back to wash the pepper. Pool.

4. The dehydrated pepper is transferred to the salt adding machine and pepper crusher, where the salt and pepper are mixed in proportion and crushed to the specified specifications, and then transported to the horizontal mixing and filling machine by the semi-circular groove conveyor , The horizontal mixing and filling machine can start filling after mixing salt and pepper evenly.

Previous Page

Next Page

Previous Page

Next Page

Online Inquiry

Hot info