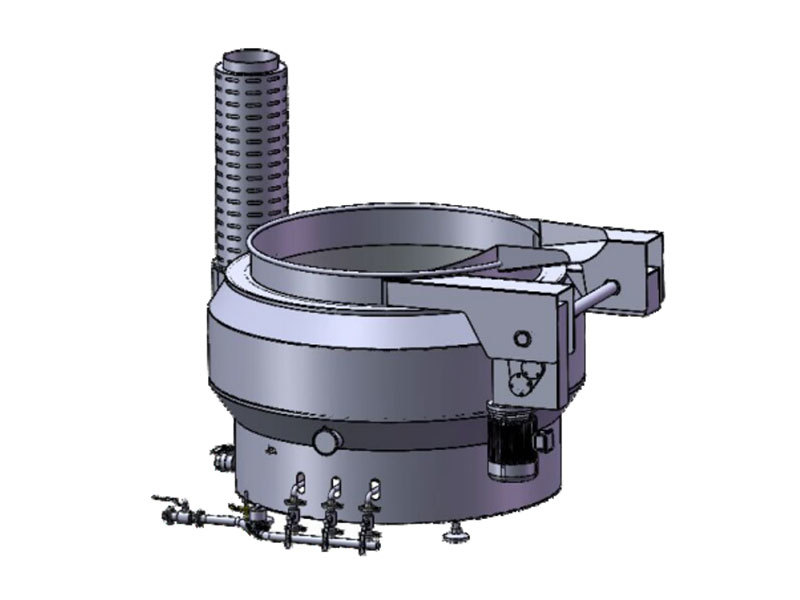

Douban paste production line

Professional manufacturer of condiment machinery

Product Description

1. The use of roller type continuous scalping line can effectively kill the bacteria in the raw materials, which is beneficial to the later inoculation of koji making.

2. The broad bean petals can be cooked in boiling water to mature the raw materials, denature the protein, and have a good koji making effect.

3. The broad bean petals are first scalded in boiling water, and then enter the cold water tank. The rapid cooling makes the broad bean petals control below 40°C, which provides ideal temperature conditions for the subsequent inoculation koji making process, which can effectively shorten the koji making time, especially In winter, the effect is obvious.

4. The degree of moisture absorption of the koji material can be arbitrarily controlled to meet different production needs.

5. The hot and cold water heating time can be adjusted to make the time more accurate. The production line has a high degree of automation and low requirements on the staff, which can realize continuous production.

Online Inquiry

Hot info